Process Safety Beacon: Stored chemicals are still hazardous

This month marks the 40th anniversary of the Bhopal disaster where highly toxic methyl isocyanate (MIC) was released from a storage tank. This event caused thousands of fatalities. None of the safeguards designed to mitigate a release of MIC worked, including the scrubber, flare, and deluge system. The company did not recognize that materials in storage are just as hazardous as those being created or used in a process.

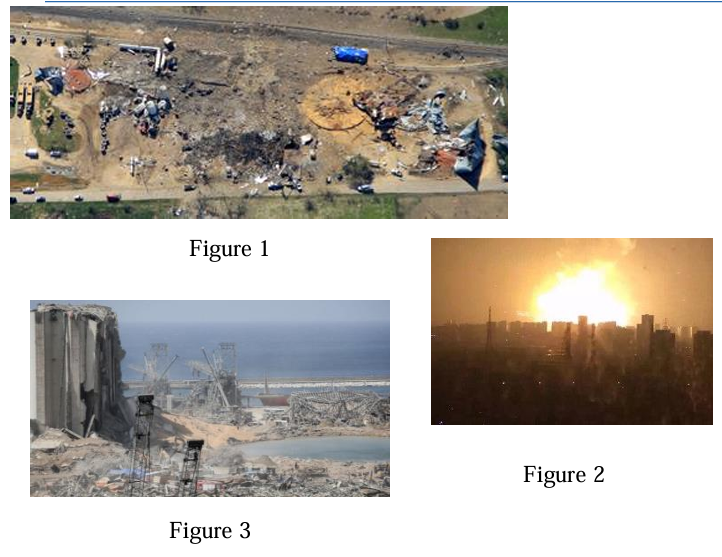

There have been many catastrophic incidents where material was in storage. Several involve ammonium nitrate (AN):

West Texas, USA (2013) fatally injured 15 injured 260. An estimated 40 to 60 tons (36 – 54 metric tons) of AN were detonated by a fire in the storage building. (Figure 1)

Port of Tianjin, China (2015) where the detonation of about 800 tons (725 metric tons) of AN caused 173 fatal injuries and 798 non-fatal injuries. (Figure 2)

Port Beirut, Lebanon (2020) 2400 tons (2,177 metric tons) of AN from an abandoned ship was stored for 6 years until the explosion. 218 people died, 7,000 were injured. (Figure 3)

Did you know?

- It is critical to understand the hazards, the amount, and the conditions of the stored chemicals.

- Tank farms and other large storage facilities are often seen as ‘just storage’ and may not get the process safety attention they deserve.

- The three AN incidents noted in this Beacon all occurred in warehouses, not tanks. Buildings storing chemicals also need to have functional process safety systems to ensure the material is properly stored.

- Some materials have a shelf life – an amount of time where they remain safe. Beyond that time, the materials may degrade, become unstable and cause a fire or explosion. If the material is no longer needed, have it removed for proper disposal.

- There have been many incidents involving hot work in tank farms. In many cases, the hazards of the materials were not recognized during the permit review and approval process.

What can I do?

- Recognize the materials currently stored in your area and know the hazards of these materials.

- When participating in PHAs, do not forget to review ALL the materials in the process, including the feed materials and products that are stored.

- If your area handles or stores materials with a known shelf life, know how they are managed. If you see materials that are near or beyond their expiration date, notify your supervisor.

- When permitted work is planned in a material storage area the hazards of the materials in the area need to be reviewed and understood before approving the permit.

Know the hazards of the materials stored in your area!

Download the latest Process Safety Beacon

Source: CCPS