Process Safety Beacon: Are your P&IDs up to date?

In 2019, an explosion followed a 10,000 lbs. (4500kg) release of flammable isobutylene from a failed Ystrainer. It fatally injured one worker and seriously injured two others. The incident also injured 28 and

resulted in the operating company’s bankruptcy. This Beacon focuses on only one of many lessons learned from this incident–the tremendous pressure that occurs when trapped liquids expand.

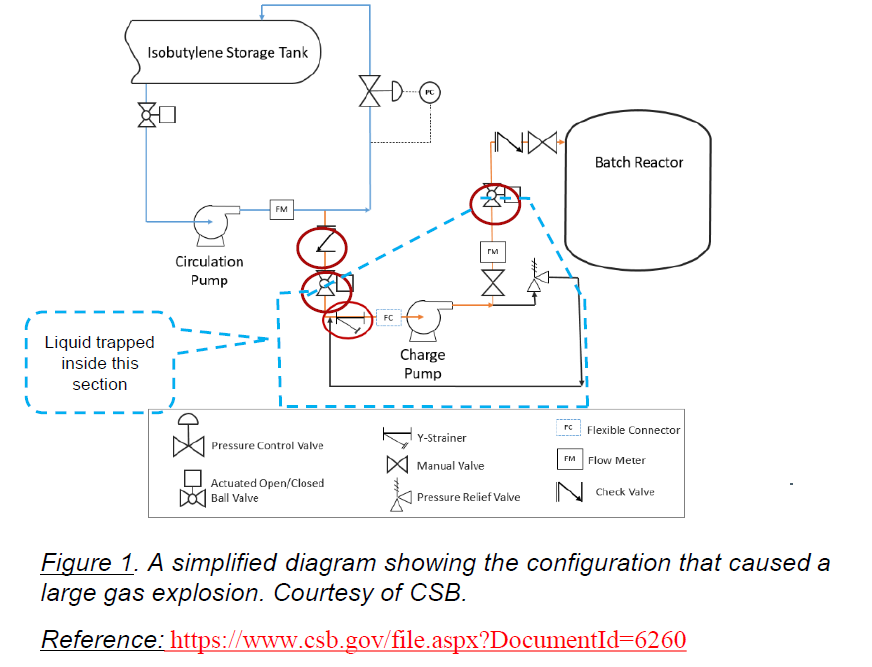

The piping & instrumentation diagram (P&ID) for the Ystrainer piping had errors (Figure 1). The version used for the process hazards analysis (PHA) did not show the Y-strainer, a check-valve nor the manually-activated isolation valves. These combined to make a section where liquids could be trapped. The facility completed an initial PHA and PHA revalidation. During both PHAs, the team did not detect the incorrect P&ID and therefore failed to recognize the liquid expansion hazard.

The drawing also indicated the piping was all welded or flanged 304 stainless steel. The 3” diameter cast-iron Ystrainer was connected to the stainless piping by pipethreaded joints which didn’t meet accepted piping specifications. (See the May 2024 Beacon)

Did you know?

- Thermal expansion of liquids can generate tremendous internal pressure on pipes and other process equipment. It can occur in blocked-in lines, especially those containing liquified gases such as isobutylene.

- The P&IDs are a key input to the Process Hazards Analysis (PHA) process. P&ID accuracy is critical to a thorough and accurate understanding of the process and its hazards.

- The PHA team reviews each section of the P&IDs, looking for things that could go wrong in that section and cause issues in that section or elsewhere.

- Good risk management practices and most process safety regulations require the P&IDs be current and accurate and used when a PHA is performed.

- PHAs are required to be revalidated or reviewed on a regular interval.

- One purpose of revalidations is to review changes that have occurred and to verify those changes are properly managed.

What can you do?

- Your P&IDs should accurately reflect the process as it exists in the field. If they don’t, report that to your supervision.

- If you are participating in a PHA study, check the P&IDs for accuracy. If they’re not correct, point this out to the team.

- A recommended practice for PHAs is for the team to visit the process area under study. These visits are an opportunity to note special hazards, safeguards or piping issues.

- If you see any threaded connections over ¾” (19mm) diameter in hazardous service, report them to your supervision.

Current & accurate P&IDs are the backbone of an effective PHA.