Process Safety Beacon: Corrosion – another hidden threat

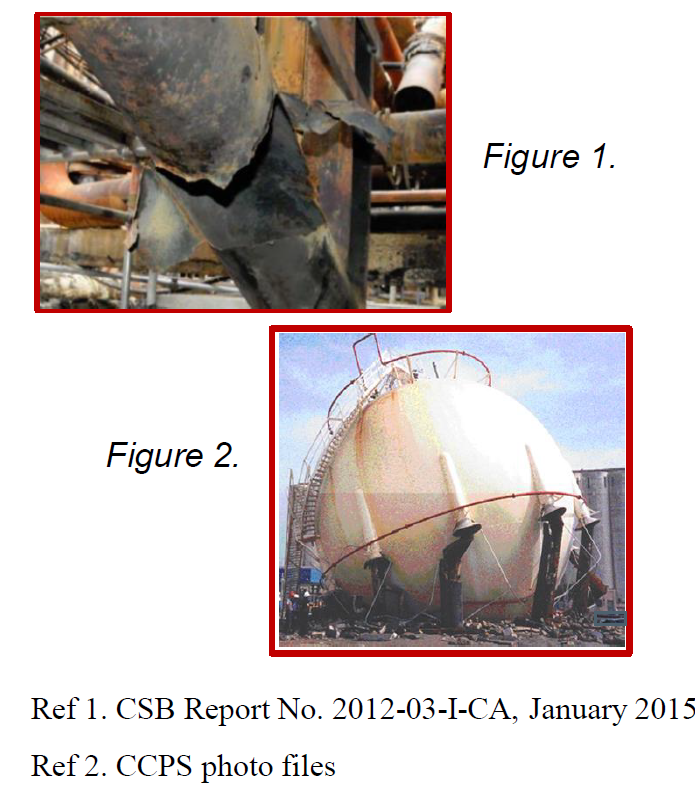

In Figure 1., an older section of piping had corroded, but a decision was made to continue operation until the next inspection. The piping failed, released hot, flammable liquid, that formed a vapor cloud. It ignited and caused a large fire There were no fatalities.

In Figure 2., a spherical tank in Liquified Natural Gas (LNG) service was being hydro tested. Water (specific gravity of 1.0) was used as the test material but is over twice as dense as LNG (specific gravity = 0.45). The legs of the sphere were fire-proofed and no one recognized that corrosion had occurred under the fireproofing. The additional load of the water caused the legs to fail. One person was injured, and another fatally injured.

Did you know?

- Corrosion can occur inside and outside of process equipment, and on support structures.

- Corrosion is a reaction between a material, usually metal, and its environment. The most familiar is the corrosion of iron or steel to form iron oxides or rust.

- There are many mechanisms for corrosion. The figures show only two.

- Most corrosion mechanisms are slow and take years to cause equipment failure. However, under some conditions, corrosion can be surprisingly fast.

- Corrosion rates are typically stated as milli-inches per year or micrometers (microns) per year (1 milli-inch = 25.4 micrometer). When reviewing corrosion data, it is important to know which units were used to measure the corrosion rate.

- Concrete can be corroded by acidic materials. This can degrade the effectiveness of containment systems for tanks, piping, and loading/unloading operations.

- Not all corrosion involves metals. Gaskets, O-rings, and other non-metal parts can fail from material attack.

What can I do?

- When making rounds, watch for signs of corrosion such as discolored insulation, stains on equipment, piping, or structures, and damaged concrete.

- Watch for places where insulation has been damaged and water can saturate the insulation or fireproofing.

- Material dripping from insulated lines it may indicate that the insulation has been damaged, but it could also be a leak. Treat all ‘drips’ with care and report them to your supervisor. Do not try to identify the leak without proper PPE.

- When opening piping and equipment, examine the gaskets and O-rings. If they show signs of attack such as discoloration or cracks, point this out to your supervisor. It may indicate the gasket or O-ring material is not correct for the present service.

Corrosion – it is inside, outside and all around your plant

Download the latest Process Safety Beacon

Source: Process Safety Beacon