Process Safety Beacon: Knowing ‘why’ makes tasks safer

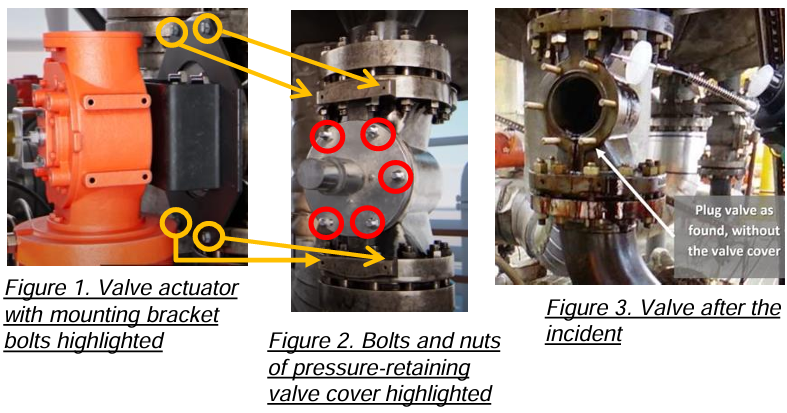

In 2021, three contract workers at a facility in La Porte, Texas, were removing the actuator from a plug valve. The actuator was being removed so the valve could be used as an energy isolation device for a piping repair job. When they removedthe actuator, the workers inadvertently removed pressure-retaining components on the valve and the pressure ejected the plug from the valve body. Approximately 164,000 pounds (74,545 kg) of acorrosive and toxic mixture of glacial acetic acid and methyl iodide erupted from the open valve body. All three contractors were sprayed with the mixture. Two of the workers were fatally injured. Another contract worker and a company responder were seriously injured. Twenty-nine other people were transported to medical facilities for further evaluation and treatment. (ref CSB report No. 2021-05-I-TX)

A similar incident occurred in Baton Rouge, LA in 2016. That incident caused a release of isobutane, which ignited and severely burned four workers. (ref CSB report No. 2016-02-I-LA and CCPS Beacon, December 2021).

These incidents had three common factors:

1. Contractors or operators did not have a procedure for removing the actuator.

2. Contractors or operators were not trained on removing the actuator.

3. Other workers were in the area assisting with the actuator removal who could have pointed out the wrong bolts were being removed.

Did you know?

- All critical tasks require a procedure.

- Both maintenance and operating procedures need to be written so they are easily understood by those who will be using them.

- Critical procedures should require the user to have the procedure with them at the location when performing the task.

- Training should require the trainees to demonstrate they understand the training and can perform the task correctly.

- To increase the probability that a task will be performed correctly, it is important that the trainees understand why the procedure needs to be performed in the specified way.

What can you do?

- If there isn’t a procedure –STOP WORK and review how to do this task safely.

- When you develop or review procedures for hazardous or critical operations, use diagrams and pictures to highlight key risk factors.

- Checklists with a sign-off also make procedures more effective.

- Ask your supervisor questions when instructions are not clear.

- During training, ask questions to understand why a task is performed in the specified way.

- When training others, take the time to explain why and how a critical task is performed and patiently answer questions.

- When reviewing or revising procedures, take them to the work location to verify the procedure matches the field conditions.

Training + Procedures + Understanding ‘Why’ = Success

Download the latest Process Safety Beacon

©AIChE 2025. All rights reserved.